hardness test lab report

6061 Aluminum Rockwell B Test Brinell 10500 Hardness Test Average 53825 956 Conversion table value 54 87 Table. Primarily on a laboratory basis.

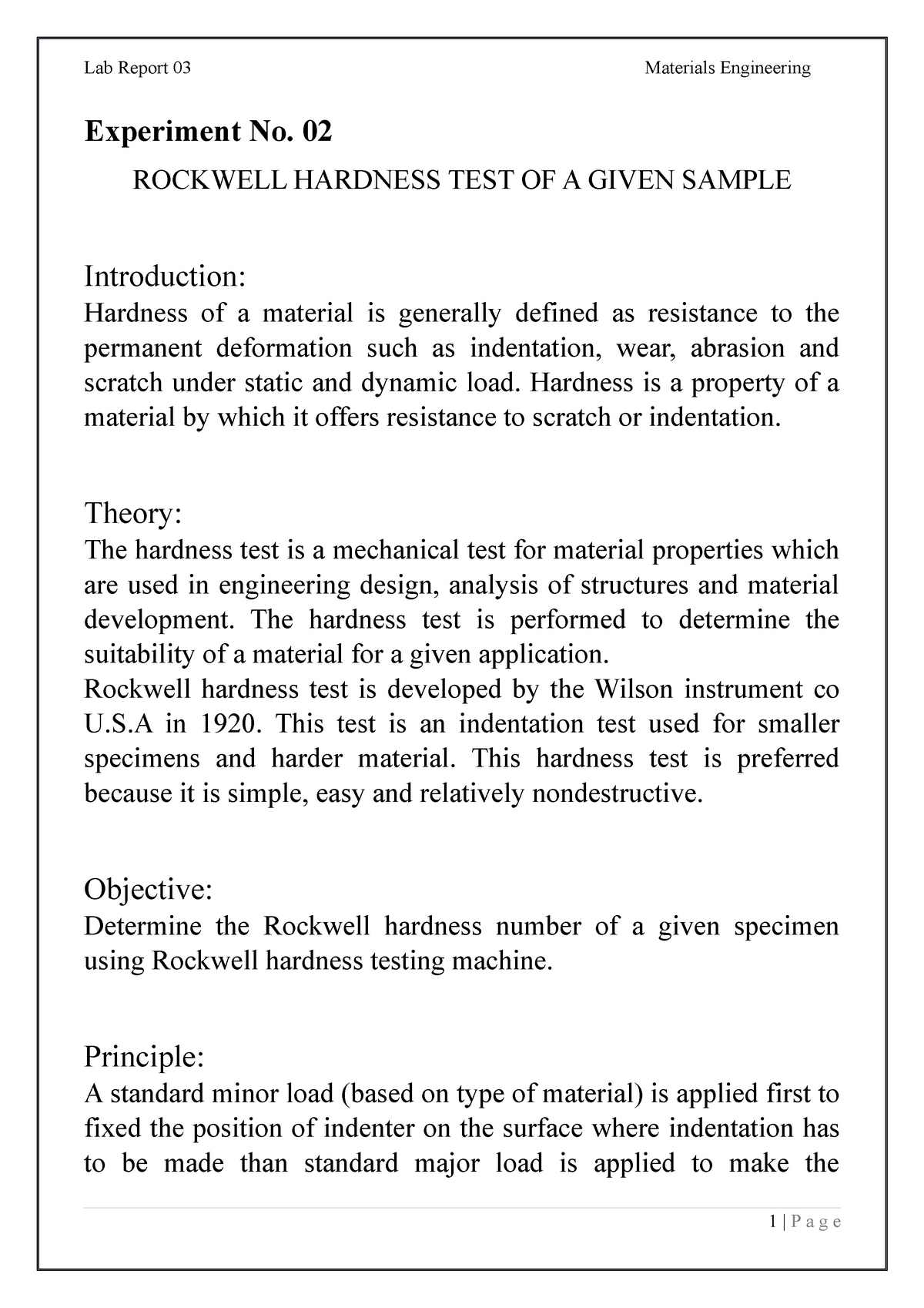

Lab Report 03 Experiment No 02 Rockwell Hardness Test Of A Given Sample Introduction Hardness Of Studocu

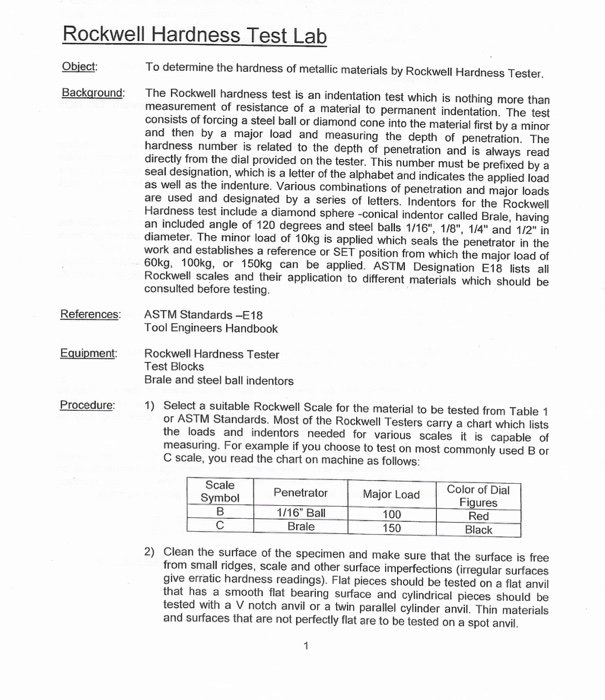

Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test.

. Hardness Testing Lab Report. P DD D D. The Brinell hardness number HB is obtained by dividing the size of the load applied by the surface area of the spherical indentation A mm2.

4 A For first reading. PdfFiller allows users to edit sign fill and share all type of documents online. The force applied by the hardness tester is set to 10kN and pressure applied to the specimen metal for 10 seconds.

Cold working and annealing can also be investigated by employing hardness testing to determine the hardness values after different conditions. Rockwell hardness testing machine. Its height was 7 mm and width was 25 mm.

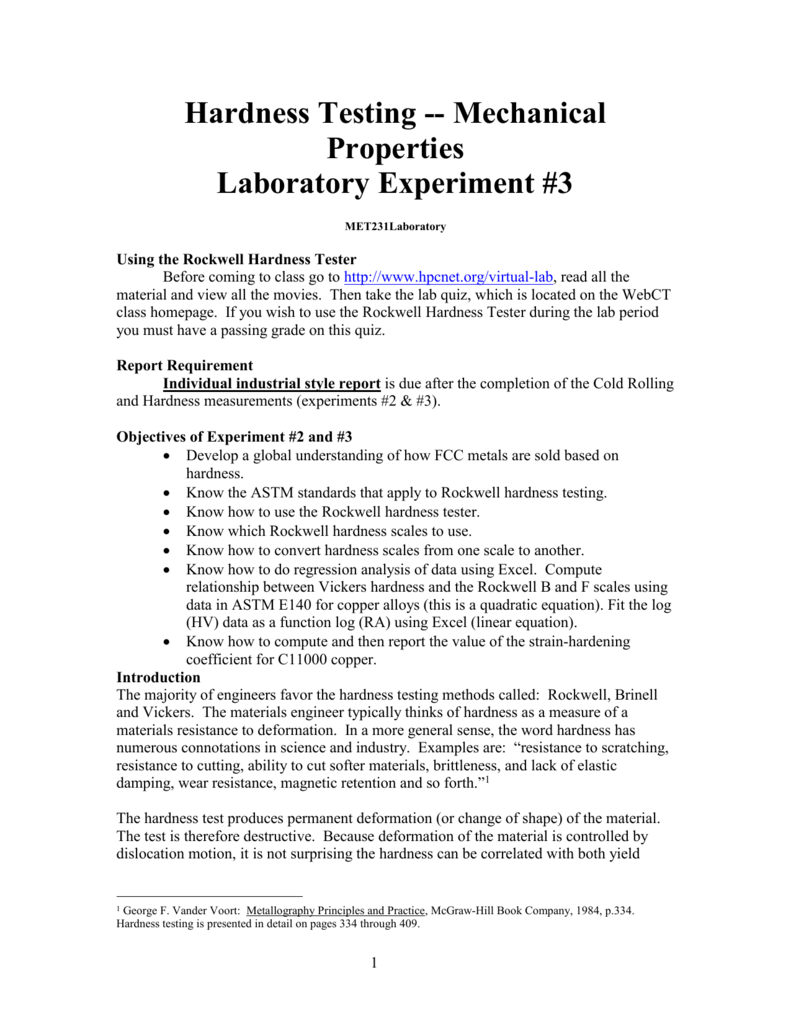

The Brinell Hardness Number BHN is obtained by dividing the applied force P in kgf. The results should contain. Vickers Hardness Test Report.

Hardness is defined as a measure of a materials resistance to localised plastic deformation i. Example both the hardness test and the tensile test measure the resistance of 2 Hardness Testing Hardness Testing 2nd Edition 06671G. RESULTS DISCUSSION Results Parameters First Reading Second Reading Third Reading D1 µm 1531 1517 1535 D2 µm 1590 1517 1535 Hardness HV 1523 1611 1574 Average Hardness HV 1569 Calculations Vickers hardness number is designated by HV where P Load in kg and d1 Arithmetic mean of the two diagonals D1 and D2 in mm.

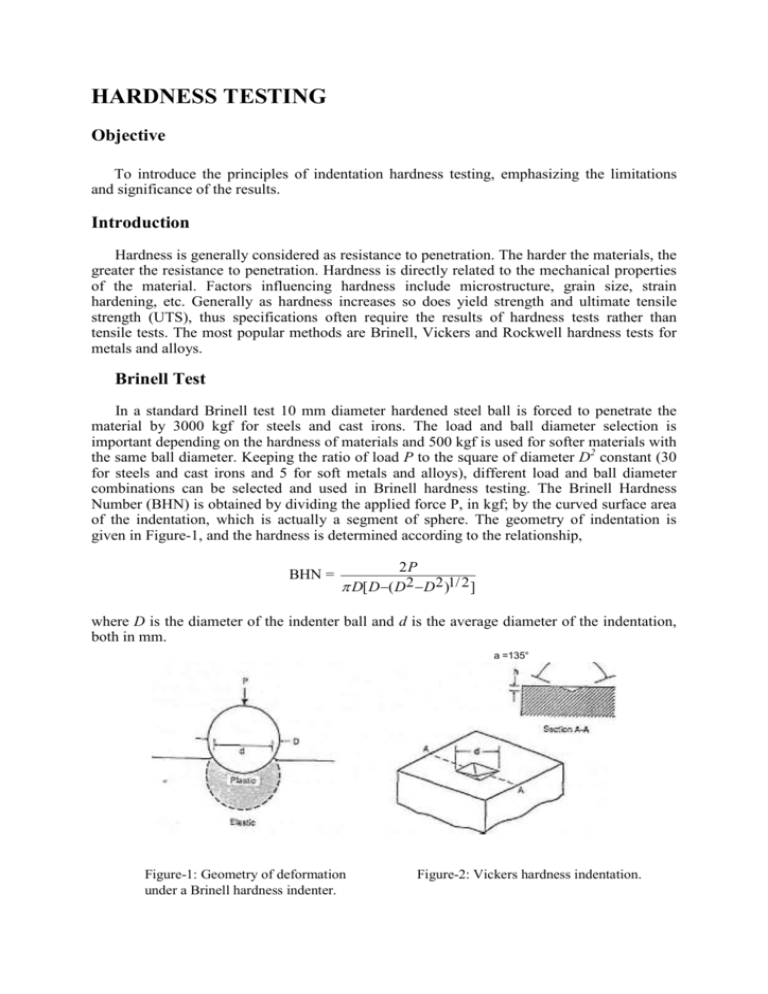

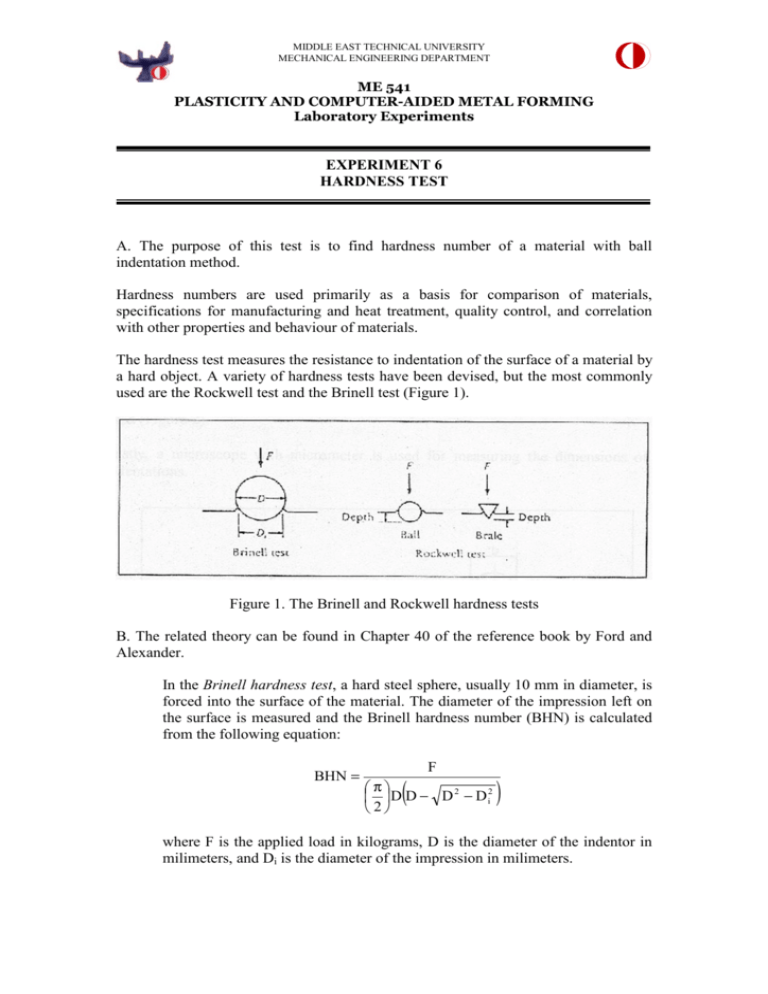

The geometry of indentation is given in Figure-1 and the hardness is determined according to the relationship BHN 2 2212. By the curved surface area of the indentation which is actually a segment of sphere. Ad signNow allows users to edit sign fill and share all type of documents online.

Brinell Hardness Test For Brinell hardness test. Hardness Testing Quang Nguyen School of Engineering Grand Valley State University Laboratory Module 4 EGR 250 Material Science Engineering Section 902 Instructor. Hardness Testing Lab Report study the hardness of different types of materials and to understand the significance of this property in materials.

Ad Download or Email Hardness Test Report More Fillable Forms Register and Subscribe Now. For soft or very hard materials the Brinell test cannot be used. Professor Lindsay Corneal October 27 2016 Abstract The purpose of this experiment were to utilize the hardness as an index of mechanical properties to relate the mechanical properties of ferrous and metal to.

The results obtained showed that the aluminum sample HB of 1173559 kgmm2 has a higher hardness than the steel sample HB of 11060855 kgmm2. In this lab we will be determining the indentation hardness of four different metals Aluminum 7075 T-24 Aluminum 6061 T-6 AISI Steel 1045 and AISI Steel 1018. The purpose of the following experiments is to study the hardness of different types of materials and to understand the significance of this property in materials.

LABORATORY REPORT NUMBER 002. Cavity diameter measured from the Brinell hardness machine is converted into the Brinell hardness number by the help of following formula. The Vickers hardness test was developed in 1921 by Robert L.

Hardness values for aluminum. One of the better known is the Spencer Bierbaum instrument. A Keep the loading and unloading lever at position A which is unloading position.

The Vickers hardness test follows the Brinell principle in that an indenter of definite shape is pressed into the material to be. The materials and the aforesaid property have significant use in civil engineering. GROUP A SUB GROUP A2.

D is diameter of the ball used for indentation. Di ameters of the different Balls used in Brinell Hardness Test. Rockwell B Test Brinell 10500 Hardness Test Average 997 2275 Conversion table value 95 220 Table.

The purpose of the following experiments is to study the hardness of different types of materials and to understand the significance of this property in materials. As seen in the theory previously presented this implies that aluminum is more resistant to. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of the material.

The materials and the aforesaid property have significant use in civil engineering. A small dent or a scratchRockwell and Brinell are popular hardness testing methods In a hardness test a small indenter is forced into the surface of a material to be tested and the size or depth of the resulting indentation is measures which in turn is related to a hardness number. Subsequently the diameter of the impression on the sample was measured by a vernier caliper and then repeated three times to reduce the error in the experiment and the average value was obtained.

Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. HB 2F πD D- D-d Here. After that the diameter of the indentation d mm is measured when the load is removed.

Where h mm is the depth of indentation D mm is the diameter of the ball. 1 Tables recording the readings and hardness number of all the specimens refer to the Log Sheet 2 Plot of Hardness v Carbon Content for the Plain Carbon Steel for each hardness test. The materials and the aforesaid property have significant use in civil engineering.

HARDNESS TESTING PURPOSE The purpose of this exercise is to obtain a number of experimental results important for the characterization of the mechanical properties and performance of materials. Different Types of Hardness Testing Methods. INDENTATION OF A METAL BY A BALL.

The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F kgf. The hardness test is a mechanical test for material properties which are used in engineering design analysis of structures and materials development. D is the diameter of the impression produce by the ball on the work piece.

Ad Download or Email Hardness Test Report More Fillable Forms Register and Subscribe Now. F is the load applied. Hardness testing is employed as a non-destructive testing NDT technique on materials.

The Leading Online Publisher of National and State-specific Legal Documents. Hardness Testing Lab Report. Hardness is a measure of a materials resistance to localized plastic deformation eg.

Smith and George E. There is no absolute scale for hardness. The specimen Al 2024 which was consist of 38-49 Cu 12-18 Mg 03-09 Mn and Fe Cr Zn Ti in a little amount had been inserted into a furnace set at 500oC approximately 50 minutes for a solution treatment before the lab.

Create Legally Binding Electronic Signatures on Any Device. B Select suitable indentor weights according. It can be used to check if the correct heat treatment was conducted on steels and for age hardening of alloys.

Selection of Load in Brinell Hardness Test. 3 Plot of Hardness v Tempering Temperature for the High Speed Steel for each hardness test. Rockwell Hardness Testing Lab Report Sample.

DEPARTMENT OF MECHANICAL AND MANUFACTURING ENGINEERING. There are three types of hardness that can be determined for a material. This is essentially the resistance of the surface of a material to deformation.

Scratch hardness indentation hardness and rebound hardness.

Doc Experiment 3 Hardness Test Siti Syairah Academia Edu

Ch Har2 2 Me 336 102 Lab 2 Hardness Abstract The Objective Of This Experiment Is To Become Familiar With The Rockwell Hardness Test And Be Able To Course Hero

Hardness Experiment Reading Assignment Callister Section 6 10

Pdf Laboratory Manual For Hardness Test

Determining Brinell Hardness Using A Standard Non Destructive Brinell Hardness Test Youtube

Doc Experiment 3 Hardness Test Min Yih Academia Edu

Solved Rockwell Hardness Test Lab Object Background The Chegg Com

Solution Hardness Test Lab Report Studypool

Solution Hardness Test Lab Report Studypool

Doc Lab 1 Hussain Ahmad Academia Edu

Experiment 6 Hardness Test A The Purpose Of This Test Is To

Hardness Test Lab Report Pdf Hardness Tests

Experiment Rockwell Hardness Test 1 0 Objectives 1 1 Chegg Com

168547658 Hardness Test Lab Report Pdf Objective To Determine The Hardness Of Various Engineering Studocu

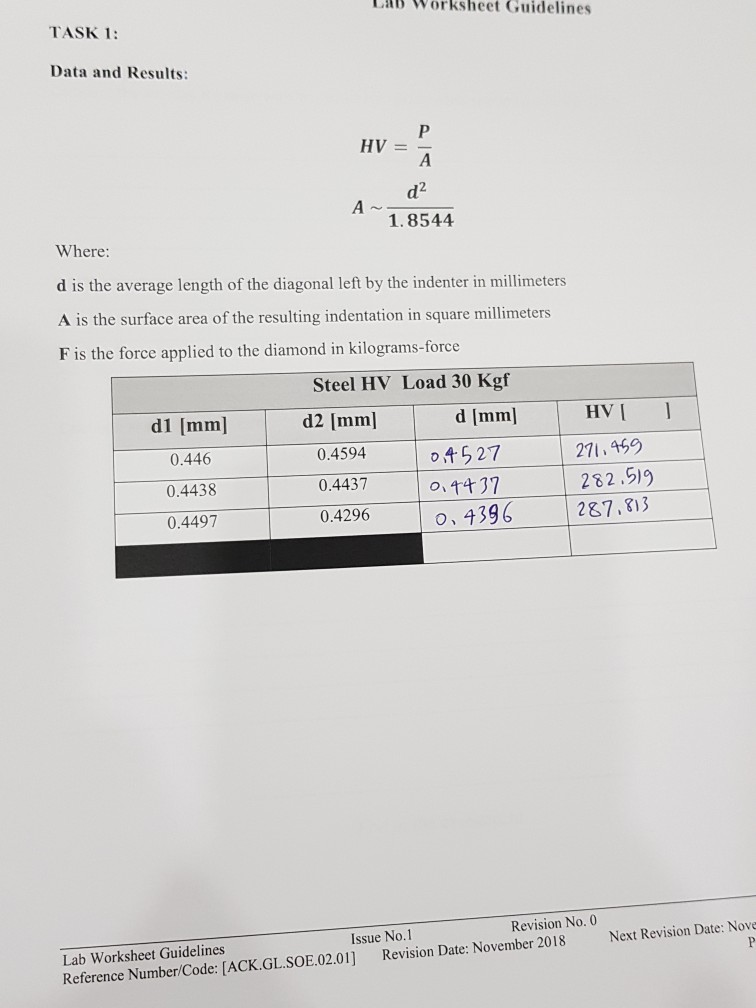

Solved Lab Worksheet Guidelines Task Details Experiment 4 Chegg Com

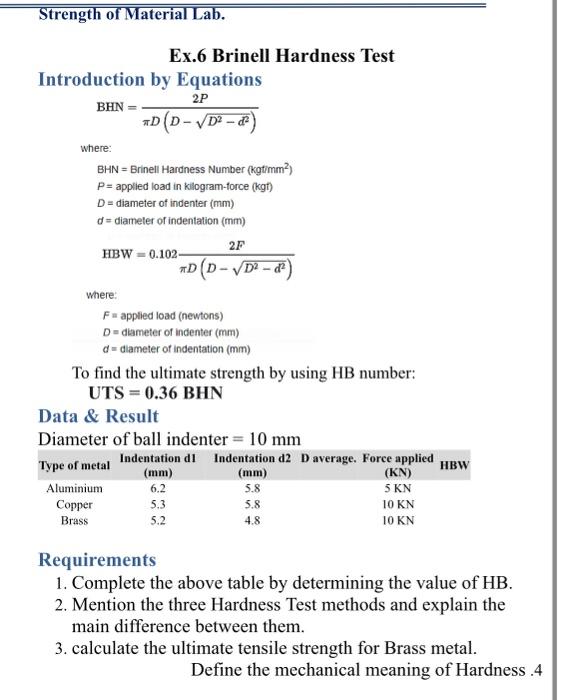

Solved Strength Of Material Lab 2p Ex 6 Brinell Hardness Chegg Com